Home

Home

Knit With Confidence

Real Time AI Fabric

Inspection.

Get customized inspection reports

according to your set standards

(ex 4-point report system)

Eliminates

Fabric Wastage

Automates

Inspection

Minimizes Operator

Dependency

Enhance

Productivity

Assure Quality

Real Time AI Fabric

Inspection

according to your set standards

(ex 4-point report system)

Eliminates

fabric Wastage

Automates

Inspection

Enhance

Productivity

Assure Quality

Minimizes Operator

Dependency

Minimize Costs,

Maximize Control.

Maximize Control.

1. Monitors fabric

in real time

2. Performs

AI analysis

3. Stops machine when

the defect occurs

4. Alerts

operator

5. Generates

inspection reports

With KNIT i, the machine stops instantly when a defect arises on the fabric.

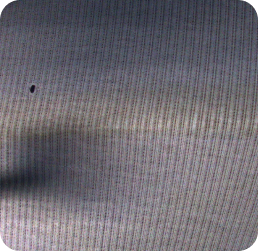

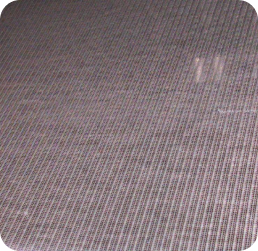

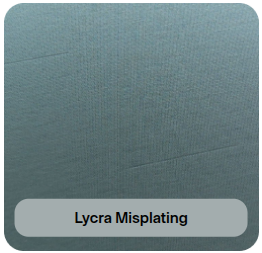

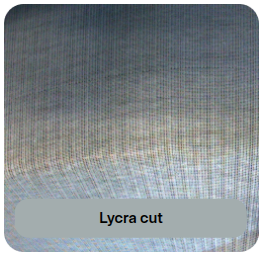

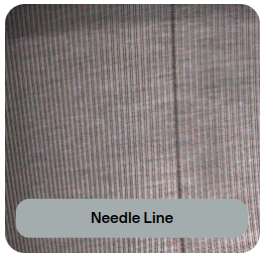

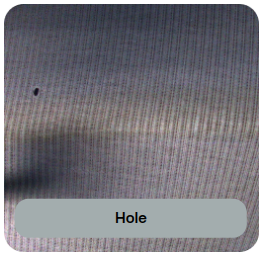

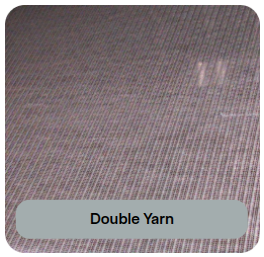

Defects Captured

by Knit i

KNIT i's algorithm is equipped to detect all essential fabric defects on your knitting machines.

Its effectiveness is proven daily across 100+ installations.

KNIT i: Solving the Challenges of

Modern Textile Production

Modern Textile Production

Centralized Dashboard

Stay informed, stay ahead

Live monitoring with KNIT i’s intuitive dashboard helps supervisors,

managers and executives to access the current and past data with ease.

Get live notifications and alerts of any irregularities in your production

(Like high stoppage time or excessive fabric defects).

Calculate Your Benefits

Automate Inspection

Witness tenfold decrease

in fabric waste

in fabric waste

Men and Machine

For Continuous Improvements

Fabric Types

Single Jersey

Double Jersey

Jacquard

Machines

Sorem ipsum dolor sit amet, consectetur adipiscing elit. Etiam eu turpis molestie,

dictum est a, mattis tellus. Sed dignissim, metus nec fringilla.

Single Jersey

Double Jersey

Jacquard

Sorem ipsum dolor sit amet, consectetur adipiscing elit. Etiam eu turpis molestie,

dictum est a, mattis tellus. Sed dignissim, metus nec fringilla.

Single Jersey

Double Jersey

Jacquard

maintenance is remarkably simple.

and hardware makes it easy for

any operator to adapt.

and we're available 24/7 for assistance.

conditions of the mill environment -

Heat, oil, and dust.

KNIT i can inspect across

all the circular knitting machines.

all the circular knitting machines.

Best Color

Aarti International

Best Color

Aarti International

Unleash the Power of KNIT i

at your Mills

Unleash the Power of KNIT i

at your Mills

at your Mills

adipiscing elit. Etiam eu turpis

adipiscing elit. Etiam eu turpis

adipiscing elit. Etiam eu turpis

adipiscing elit. Etiam eu turpis

Real Time AI Fabric

Inspection

according to your set standards

( ex 4-point report system)

Eliminates

fabric Wastage

Automates

Inspection

Enhance

Productivity

Assure Quality

Minimizes Operator

Dependency

Knit With

Confidence

Minimize waste

Minimize waste

Automate and control Quality

Automate and control Quality

Boost productivity

Boost productivity

is the Next Big Step.

With real-time fabric inspection on your circular knitting machines, eliminate your fabric wastage, reduce the dependency on operators, and run the mill

with absolute confidence!

Real Time

AI Fabric Inspection

AI Fabric Inspection

standards (ex 4-point report system)

Inspection

Productivity

Minimize Costs,

Maximize Control.

Maximize Control.

1. Monitors Fabric

in Real Time

2. Performs

AI Analysis

3. Stops Machine

when the defect occurs

4. Alerts

Operator

5, Generates

Inspection Reports

with KNIT i, the machine stops instantly when

a defect arises on the fabric.

Defects Captured

by Knit i

by Knit i

fabric defects on your knitting machines. Its effectiveness is

proven daily across 100+ installations.

KNIT i: Solving the Challenges of Modern Textile Production

Centralized Dashboard

supervisors, managers and executives to access the

current and past data with ease.

Get live notifications and alerts of any irregularities in

your production (Like high stoppage time or excessive

fabric defects).

Calculate Your

Benefits

Benefits

Savings

Productivity

Eliminate Fabric Loss

in fabric waste

Data

Improvements

KNIT i is

Guaranteed

Guaranteed

maintenance is remarkably simple.

makes it easy for any operator to adapt.

and we're available 24/7 for assistance.

conditions of the mill environment - Heat,

oil, and dust.

KNIT i can inspect across

Our Client’s

words.

words.

We are delighted by the results achieved by our customers

Best Color

After initially installing Knit-i on a few machines, we’ve now equipped all our knitting machines with it. This has allowed us to control waste, digitalize and track fabric defects, and, most importantly, eliminate the need for quality control within the knitting process.

Aarti International

Knit-i offers substantial benefits, and we had been eagerly awaiting such a solution. The team’s service response has been outstanding, and we are pleased to partner with the Knit-i team.

After initially installing Knit-i on a few machines, we’ve now equipped all our knitting machines with it. This has allowed us to control waste, digitalize and track fabric defects, and, most importantly, eliminate the need for quality control within the knitting process.

Best Color

Aarti International

Unleash the Power of KNIT i at your Mills

Unleash the

Power of KNIT i at

your Mills

Power of KNIT i at

your Mills

WhatsApp us